Smart Liquid Supply System

“Easy, simple and quick change between different coating mixtures, that is the simplicity of our Smart Liquid Supply System”

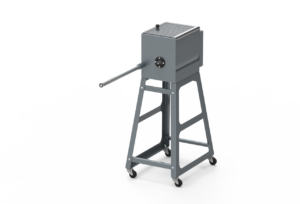

With the“Smart Liquid Supply System” you can accurately dose individual components together to your coating process. This means that no premixing is required. Each component will be simultaneously dosed into the special static mixer and measured by a weigh-out system.

Each container has its own small dosing/mixing device (mixing to prevent liquids from settling inside this container). Each ‘storage container’(IBC etc.) needs to have a mixer as well. We can include 30L plastic containers for (pre-) storage of the components (see left of IBC’s on picture below. Each component will be dosed into mentioned intermediate 3L or 1L dosing/mixing container by gravity. A pneumatic valve automatically opens when re-filling is required.

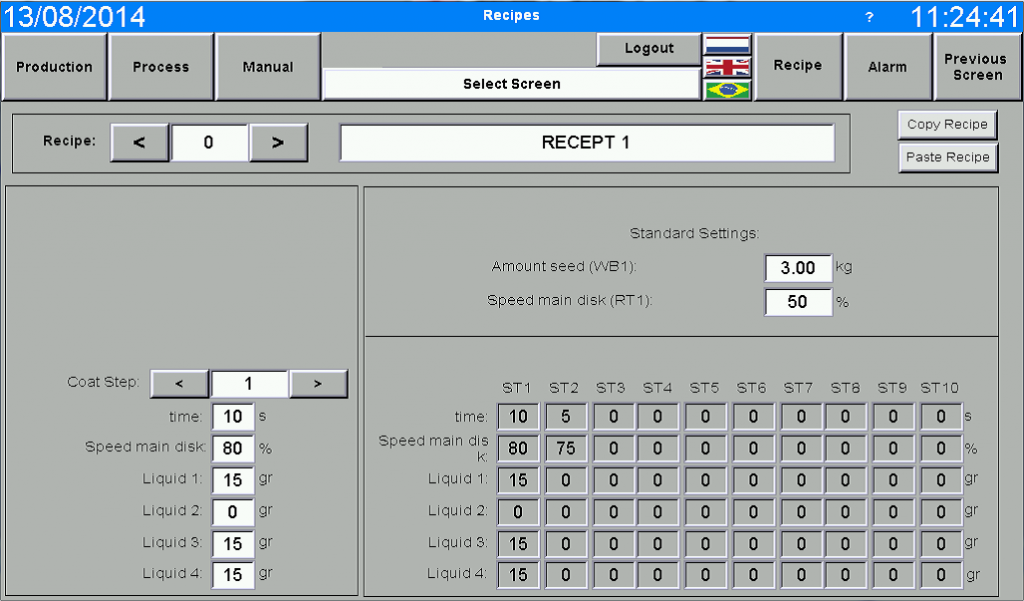

All functions of this liquid mixer can be easily controlled combined with a Hoopman HRXXX system. We can also supply the system as an “Stand Alone” version to use with already in use systems. Each individual component can then be set in the specific coating recipe. The machine will take care of the dosing in production.

Connect, Pull-Up, Recipe and Coat!

No pre-mixing

No rest-slurries

No exposure to actives