Batch Drying System BD300\600

“Fluid-Bed drying with high capacities and easy to use drying box”

These dryers are designed for drying bigger lots of coated, pelleted or treated seeds. The technical design is basically our BDS drying system but with all advantages of a removable drying box. This gives you the opportunity to load one box while the other box is being dried. The boxes are designed to fit in already existing hot-water treatment plants for wooden boxes.

We can offer other sizes of dryers that will be designed according to your specific needs. These may also include “On Spec” Complete system for constant air conditions that are needed in very hot and humid conditions

Description

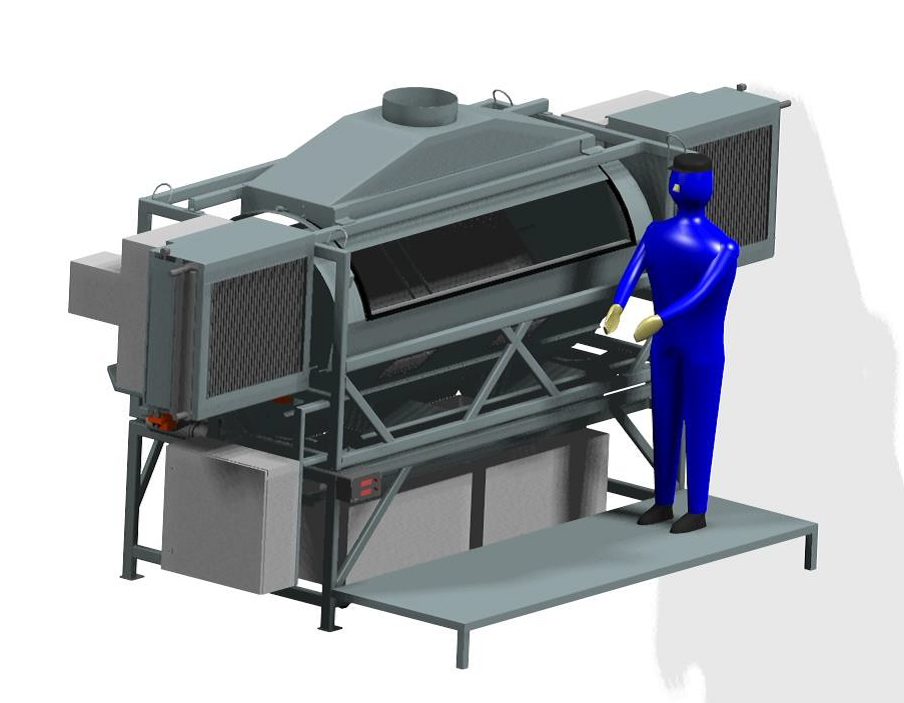

BD-300 Box Drying System

“Fluid-Bed drying with high capacities and easy to use drying box”

The drying box will be placed into the machine and is held in place by specially designed clamps. At the beginning of the process the dust extraction hood closes so that all seals are compressed and no air is lost during the drying process. Because the complete frame is placed on load-cells you can monitor the moisture decrease during the complete drying process. Another advantage of this system is that in the beginning of the process the complete box tilts backwards/forwards to have a homogenous fluidisation as soon as possible.

All these features where already tested and designed in our BDS systems. But the biggest advantage of this BD system is the possibility to remove the box from the dryer and use it for transport / rinsing /treatment. The box is built of stainless steel and has special corners to be sure that the complete box is in fluid-bed while drying. The box can also be emptied with standard in use box tippers.

The system is controlled with a PLC and HMI which gives you the opportunity to set drying protocols with several steps (to slow down the fan when seeds get dryer), dry to pre-set weights and even a logging of all data is included.

Specifications

√ Steel powder coated frame

√ Stainless steel box is included

√ Standard with hot-water heat exchanger (several options available)

√ Control box with:

o PLC controlled drying

o Frequency controlled fan

o Air temperature in-out and monitoring of Seed temperature

o Weight controlled drying (with logging)

o Drying on pre-set protocols

√ Pneumatic dust hood to have a closed system while drying

Options

√ Air conditioning systems / recirculation systems

√Hot water treatment system

√Extra drying cylinder

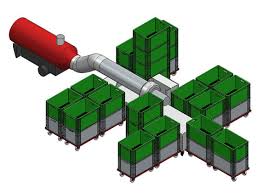

BDS-600 Batch Drying System

“High capacity batch drying system for up to 600 liters per batch”

The BSD-600 drying system is the biggest batch drying system available. It is capable to dry up to 600 litres per batch. This gives the dryer the availability to dry several batches of a HR1250 rotary coater together (approx 120litres per batch), or dry just one batch of seed. The BSD-600 is a relative compact drying system especially for encrusted and pelleted seeds, for film coating and encrusting we have also a continuous system available.

Standard equipped with

√ Process air fans Standard ready/plug-in to use (400V 3 phase 50Hz)

√ Control panel Integrated weighing system (accurate measuring of weight decrease during drying process)

√ 360º rotating system to empty out completely

√ Swinging during startup of the drying process (approx 5º)

√ Frequency controlled air fans Seed temperature control system

√ REALTIME MOISTURE CONTROL!!

Options:

√ PLC controlled with Touch Panel

√Several air conditioning units (from electrical heating op to preconditioning systems

Reviews

There are no reviews yet.