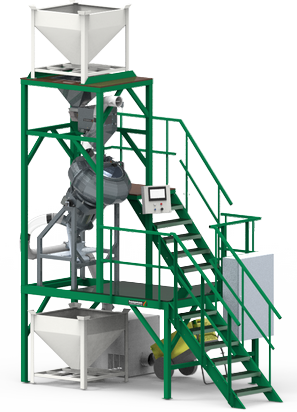

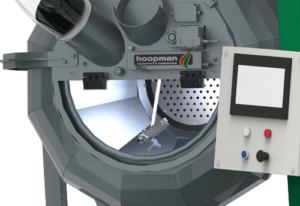

Integrated Coating and Drying

Very suitable for high loading of crop protection and/or polymer slurries on small veg seeds.

For high slurry loads, but still easy to clean and gentle seed handling!

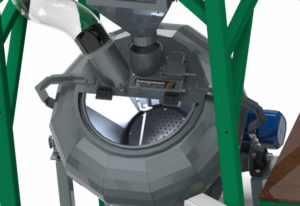

The ICD system is a perfect system when you need to coat with high slurry loads. The design based on the

conventional pelleting pan has a gentle seed handling which is important while coating easy damaged seeds such as

beans etc.