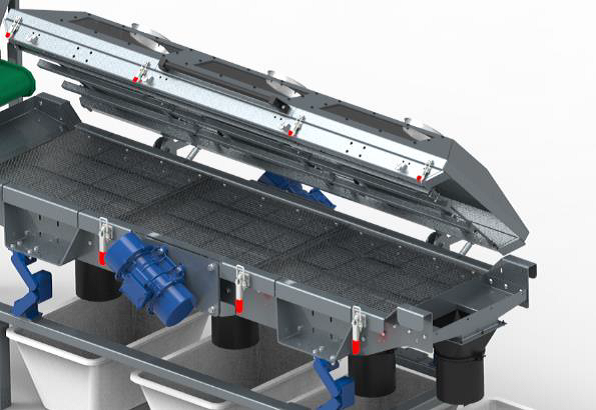

The sieve system is standard equipped with a inlet system, dust hood and control box to make it plug & play. You can place 3 sieves of 600x800mm inside the frame to sort your product into 4 fractions.

Because there is a ball-frame with balls underneath the sieve frame it will clean itself during the sieving process. By frequently vibrating at a higher speed blockage of the sieve slots will be prevented

Specifications

All advantages of our knowledge in vibratory sieving in a new design

Easy ‘no bolt – no tool’ sieve exchange, just open the clamping frame and place new sieves

Easy access for quick inspection, due to a 2 stage opening hood

4 fractions in just one run due to the space of 3 sieve plates (600x800mm)

Standard with dust hood

Standard with control box for automatic start/stop and change between low/high speed for automatic cleaning

Plug & Play and ready to use

CE industrial standard

Standard delivered with 3 sieves (dimensions on spec) and 4 holding buckets of 150l each